From Gears to Idlers: The Total Option for Trustworthy Undercarriage Parts

From Gears to Idlers: The Total Option for Trustworthy Undercarriage Parts

Blog Article

Discover Undercarriage Parts for Heavy Machinery

Understanding the intricacies of undercarriage parts is essential for the optimal performance and longevity of hefty equipment. From track footwear to idlers, gears, and rollers, each component plays an important role in the functionality of the devices. Digging into the specifics of these components reveals a world of precision engineering and durability that maintains heavy machinery operating at its top. Stay tuned as we uncover the importance of undercarriage parts and check out the maintenance techniques that can improve the performance of these crucial components.

Relevance of Undercarriage Parts

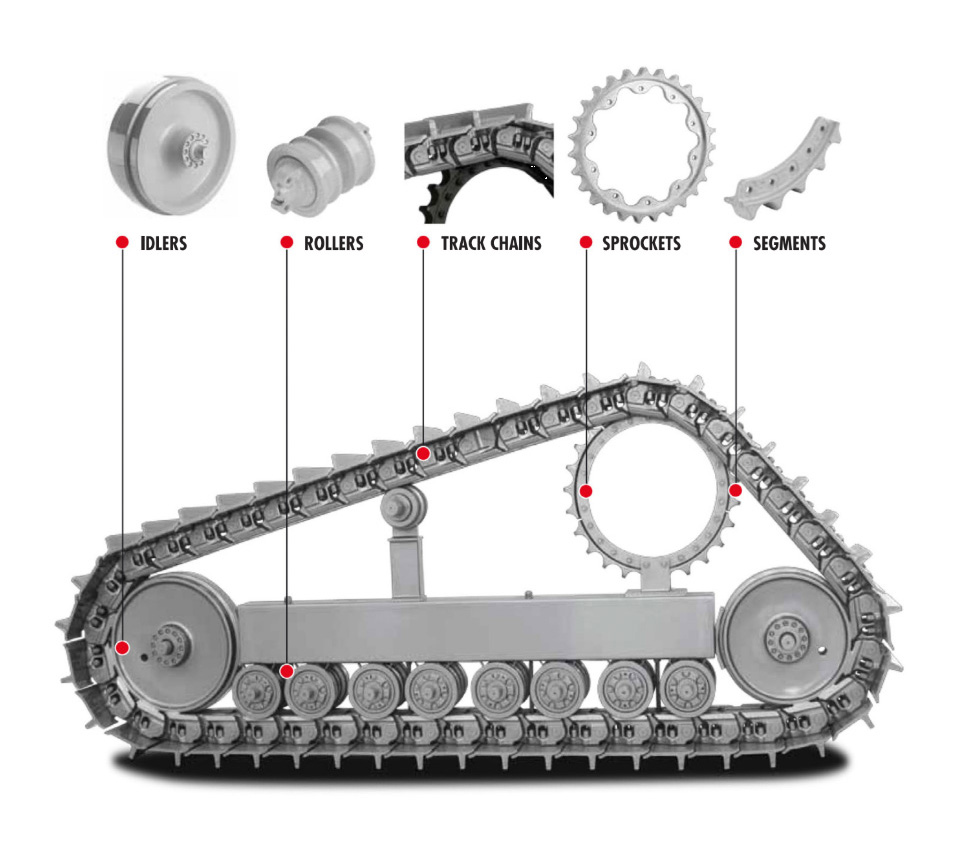

The undercarriage parts of hefty equipment play a crucial function in guaranteeing the total efficiency and longevity of the equipment. These elements, consisting of tracks, rollers, sprockets, idlers, and chains, form the foundation upon which the maker operates. A well-maintained undercarriage not only supplies security and support to the hefty equipment yet also contributes considerably to its functional performance and performance.

Among the key advantages of buying premium undercarriage parts is the reduction of downtime and upkeep costs. By utilizing resilient parts that can stand up to the rigors of heavy-duty applications, operators can lessen the demand for constant repairs and replacements, thus maximizing the equipment's uptime and total life-span.

Furthermore, properly operating undercarriage parts make sure optimal weight maneuverability, circulation, and traction, permitting the hefty equipment to operate smoothly also in difficult terrains. This integrity is crucial for sectors such as farming, mining, and building and construction, where devices efficiency directly influences job timelines and success. Finally, the importance of undercarriage components can not be overstated in keeping the efficiency and longevity of heavy machinery.

Sorts Of Track Shoes

When considering the numerous kinds of track shoes for hefty equipment, it is necessary to examine their style and functionality in connection with specific operational needs. Track shoes are critical components of the undercarriage system, supplying weight, grip, and security circulation for heavy machinery such as excavators, excavators, and spider cranes.

One of the most typical kinds of track shoes include:

** Grouser Shoes **: Including elevated metal bars (grousers) along the footwear's surface, these track shoes provide boosted grip in challenging terrains like mud, snow, and loosened crushed rock. undercarriage parts.

** Double Grouser Shoes **: Comparable to grouser shoes yet with an added collection of grousers, these track shoes supply also better grip and stability, making them perfect for incredibly harsh terrains.

** Three-way Grouser Shoes **: With 3 sets of grousers, these track footwear give optimal traction and stability, making them ideal for the most demanding conditions.

Choosing the appropriate kind of track shoe is essential for optimizing the efficiency and durability of heavy equipment while guaranteeing security and efficiency throughout operations.

Function of Rollers and Idlers

Rollers and idlers play essential duties in sustaining and guiding the track footwear of heavy equipment throughout operation. By protecting against excessive slack or rigidity in the tracks, idlers add to the general stability and efficiency of the equipment.

Additionally, rollers and idlers interact to maintain the track footwear in alignment, avoiding them from slipping or hindering off throughout operation. Effectively working idlers and rollers are vital for making sure the durability of the undercarriage system and optimizing the machine's efficiency. Routine upkeep and evaluation of these elements are vital to determine any indicators of wear or damage at an early stage, protecting against costly repair services and downtime over time.

Role of Sprockets in Machinery

Upkeep Tips for Undercarriage Components

Effective upkeep of undercarriage elements is crucial for guaranteeing the durability and optimum efficiency of hefty equipment. Regular examination of undercarriage parts such as track chains, rollers, idlers, gears, and track footwear is crucial to stop unanticipated breakdowns and costly repair work. One vital upkeep tip is to keep the undercarriage clean from debris, mud, and other contaminants that can accelerate wear and corrosion. It is also vital to make sure proper visit this web-site track tension to stop early endure parts. Oiling the undercarriage parts at suggested intervals assists to minimize friction and extend the lifespan of the parts. Monitoring for any unusual sounds, resonances, or modifications in device performance can indicate possible problems with the undercarriage that need immediate focus. By adhering to these upkeep suggestions vigilantly, heavy equipment official statement operators can reduce downtime, reduce running expenses, and make the most of the productivity of their tools.

Conclusion

Finally, the undercarriage parts of heavy equipment play a vital role in making certain the smooth functioning and durability of the tools. Recognizing the value of track footwear, idlers, sprockets, and rollers, as well as implementing proper maintenance practices, can substantially affect the total read here efficiency and efficiency of the equipment (undercarriage parts). Normal inspection and timely substitute of damaged components are necessary in optimizing the lifespan and productivity of heavy equipment

Rollers and idlers play essential functions in sustaining and assisting the track footwear of hefty machinery during operation.In heavy machinery, sprockets offer a crucial function in transferring power from the engine to the tracks, enabling the equipment to move effectively and properly. These parts are attached to the axles or last drives of the equipment and job in combination with the tracks to thrust the tools onward or in reverse. Normal inspection of undercarriage parts such as track chains, rollers, idlers, sprockets, and track shoes is crucial to prevent unexpected breakdowns and expensive repair services. Understanding the significance of track shoes, gears, rollers, and idlers, as well as implementing proper upkeep methods, can greatly influence the general performance and efficiency of the machinery.

Report this page